Custom Robotic Applications

FOR VARIOUS INDUSTRIAL APPLICATIONS

Our robotic solutions make your factory process more efficient

PALLETIZING & DEPALLETIZING

We offer contemporary solutions for single palletizing cells up to central large-scale palletizing systems of high capacities. Additionally, depalletizing systems are part of our portfolio, with visual systems (3D cameras, profilers, etc.) for product detection, especially used for sack or mixed product depalletizing.

PACKAGING

Our systems can handle case forming and case packing for any product since our grippers are also custom-made when needed and adjusted to your production specifications. We can case pack your products with utmost precision and speed, significantly reducing scraps and costs while enhancing quality at the same time.

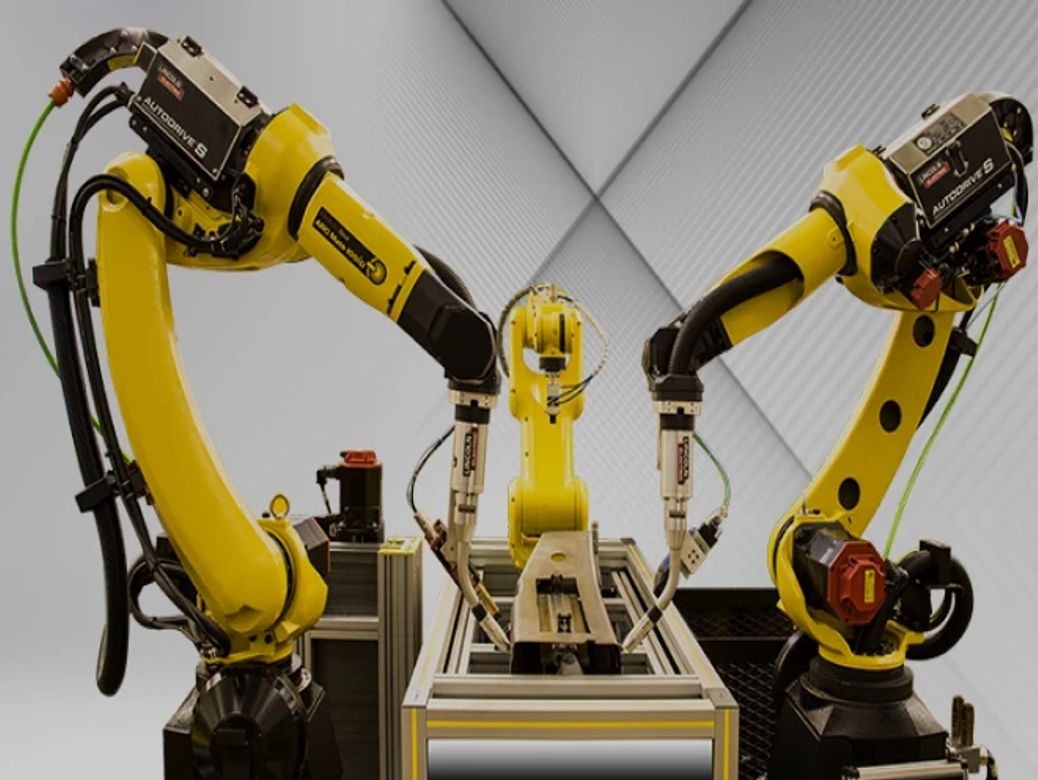

WELDING

We offer solutions for arc welding, laser welding, and even spot welding together with our partner FANUC and a variety of suppliers for welding equipment based on your needs. Steel, aluminum, or stainless steel can all be welded automatically. Robotic welding eliminates the impact of fumes, radiation, and heat associated with welding processes. Operators remain safe outside the robot’s enclosure, away from the elements damaging to their health.

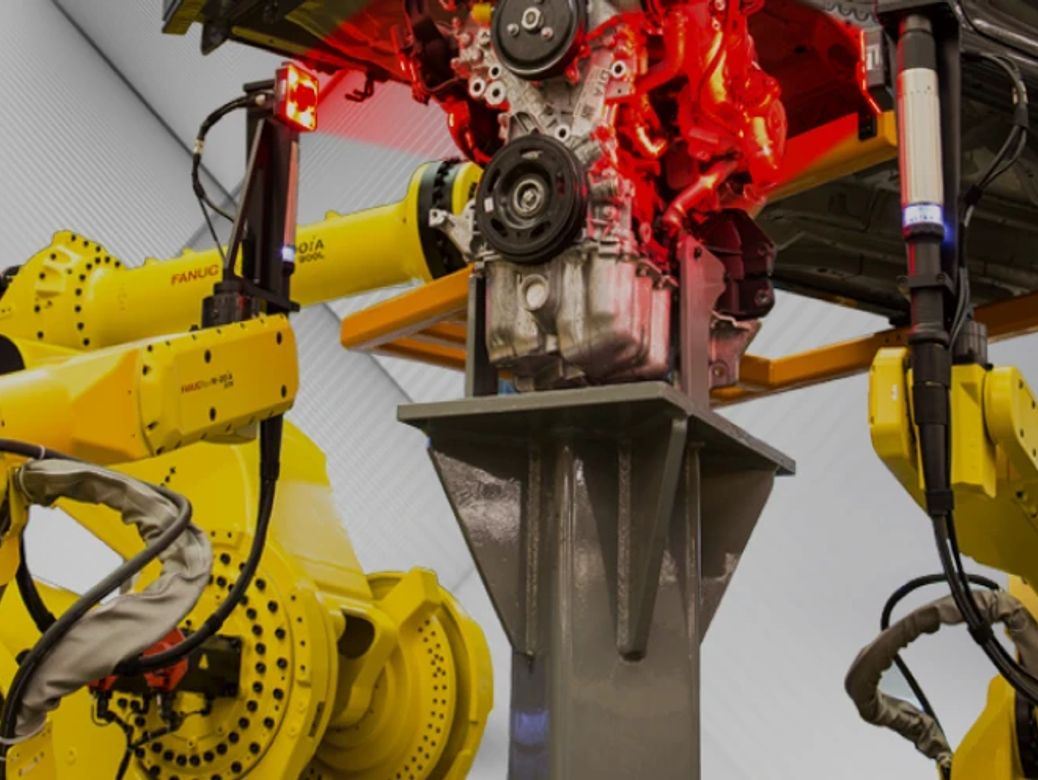

HANDLING

Industrial robots are extensively used in these applications as they offer much higher productivity. Precision in product placing is top-notch and provides for end-product consistency, whereas machine downtimes are eliminated. Robotic flexibility allows for no limitations in the tasks undertaken and enables cooperation with all machinery of an industrial unit.