The DOBOT CR12A is a powerful and versatile cobot with a payload of 12kg and a reach of 1200mm. It is easy to program with the DobotStudioPro software and can be quickly adapted to different tasks. It is particularly suitable for loading, unloading and palletising, for example.

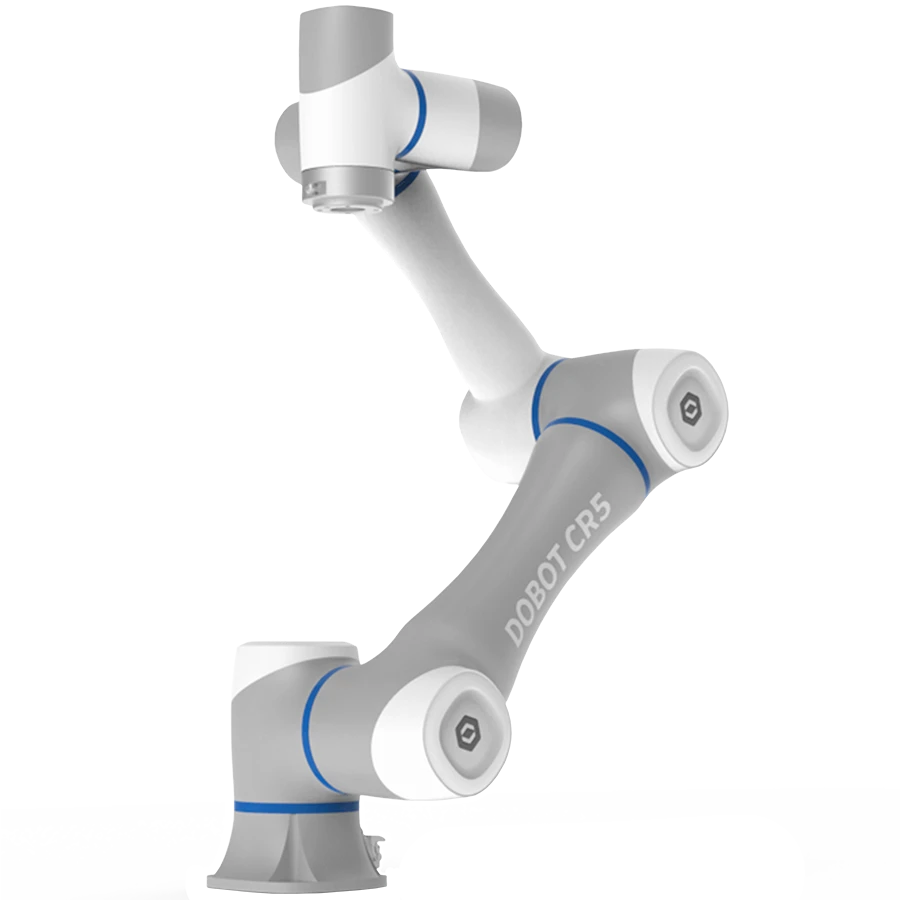

CRA series collaborative robot

A new benchmark for collaborative robot

The CRA series, the new generation of collaborative robots, incorporates high-performance integrated joints, leading to a 25% increase in the cycle time and unprecedented efficiency. The new control cabinet and DobotStudio Pro system software ensures a comprehensive enhancement in safety, stability, and scalability, and improve human-machine collaboration to a whole new level.

Fast, accurate, and stable—Unparalleled motion performance

Unparalleled speed

The latest integrated joint enhances the joint speed to 223°/s, which is the highest in the industry.

This improvement allows for a wider range of application scenarios and boosts the production cycle time of common tasks like material handling by 25%. Consequently, it generates greater economic benefits.

Fast response

The EtherCAT bus is utilized by the joint servo, providing a vast bandwidth of hundreds of megabits and a joint response speed in the millisecond range. This remarkable combination greatly enhances the robot's movement speed and trajectory smoothness, enabling it to efficiently carry out a wide range of tasks.

Accurate positioning

Each robot is precisely calibrated with a laser calibration system, ensuring an absolute positioning accuracy of under 0.4 mm.

This exceptional precision enables the robot to effortlessly tackle high-precision production tasks, thereby enhancing consistency and quality assurance in the production process.

Multiple safety measures to mitigate production risks

SafeSkin

Exclusive mass-produced

safe skin in the industry

Pre-collision sensing enhances safety and efficiency in the robots

15 cm

Pre-collision sensing

0.01 s

Fast monitoring

0.1 s

Fast response

1 m/s

Maximum human-robot interaction speed

* This is an optional accessory

Fast, accurate, and stable—Unparalleled motion performance

Simplicity and efficiency

Each robot is precisely calibrated with a laser calibration system, ensuring an absolute positioning accuracy of under 0.4 mm.

This exceptional precision enables the robot to effortlessly tackle high-precision production tasks, thereby enhancing consistency and quality assurance in the production process.

Skilled developers can effectively design intricate programs and effortlessly manage advanced applications through the provision of adaptable LUA script programming.

A wide range of ecosystem plugins is adapted to a variety of robot accessories, such as grippers, force sensors, 2D/3D vision, and etc. By directly utilizing the ready--to-use APIs from the plugins, users can efficiently accomplish application development in a short span of time.

A range of application process packages is offered for welding, palletizing, CNC, and more. By adjusting parameters, programs can be easily created, resulting in faster robot applications. Additionally, tailored and specialized process packages can be developed for specific applications.

The robot log enables you to access historical status, operation records, and parameter modification information at your convenience. This allows for swift problem identification and minimizes downtime.

Users can leverage offline programming to execute, debug, and validate programs without being connected to the robot, resulting in expedited project implementation.

Different terminals(computer, tablet, teach pendant) is supported. And wired or wireless connection methods can be chosed according to different usage scenarios.

Teach Pendant

Featuring a lightweight and compact design, the DOBOT Teach Pendant seamlessly combines aesthetic and ergonomic features,

resulting in a grip that is not only visually appealing but also comfortable to hold.

Its exceptional interaction design ensures safety, flexibility, and enhanced efficiency in robot debugging, delivering an excellent user experience.

ISO safety certification

Certified with ISO 10218-1:2011 and ISO 13849-1:2015

10.1 -inch HD capacitive screen

With a resolution of up to 1920 x 1280 and multi-touch that offers a better hands-on experience

3 -position enable button

Can be configured as a 3-position enable switch or drag-and-drop button according to safety requirements

12 physical jog button

Greatly improve the efficiency of jog teaching

* This is an optional accessory

VX500 smart camera, make cobot-vision application easier

Our robots are equipped with a 5-megapixel camera, an LED light source, and high-performance 2.5D algorithms, allowing them to integrate vision and communication functions seamlessly. They have exceptional precision in detecting changes in scene height and tilt, with an impressive spatial compensation accuracy of up to ±0.26mm. Moreover, their comprehensive error-proof detection algorithms enable the quick implementation of various vision applications, such as visual localization, measurement, inspection, and identification. The smart camera can be easily integrated with DOBOT CRA, providing a plug-and-play functionality. This eliminates the need for selecting, assembling, external wiring, and hardware and software debugging, making the process of building vision solutions hassle-free.

* This is an optional accessory

2.5D

high-performance localization algorithm

30 minutes

to start a vision application

5 megapixel

high resolution

±0.26 mm

spatial compensation accuracy